About Star Lab CNC

Building the toughest, most accurate American-made CNC plasma tables on the market. Our machines redefine performance with precision, speed, and versatility—all in one machine.

Building the toughest, most accurate American-made CNC plasma tables on the market. Our machines redefine performance with precision, speed, and versatility—all in one machine.

From Assembly Lines to CNC Plasma Tables

Our journey began in 1989 with a focus on designing and building automated hydraulic, high-speed assembly and packaging systems. Early on, our precision components found their way into the IBM Zip drive assembly line, and we later contributed to the medical industry by creating machines for packaging critical components and supplying prototypes to researchers.

As automation advanced, so did we. We recognized the need for equipment built not just for efficiency, but for the people who run it. That vision drove us to create machines that were durable, easy to use, and required little to no maintenance. Out of this commitment, Star Lab CNC was born — machines designed around the operator, not just the process.

Our machines are engineered to grow with you. Every model we build is designed to take advantage of future upgrades in hardware, software, and motion technology — even years after installation. Today, Star Lab CNC machines are cutting across the globe, backed by a trusted dealer network dedicated to helping customers choose the right solution for both today's work and tomorrow's opportunities.

From IBM assembly lines to medical devices, from automation to CNC plasma tables - our expertise spans decades and industries, all focused on building machines that last.

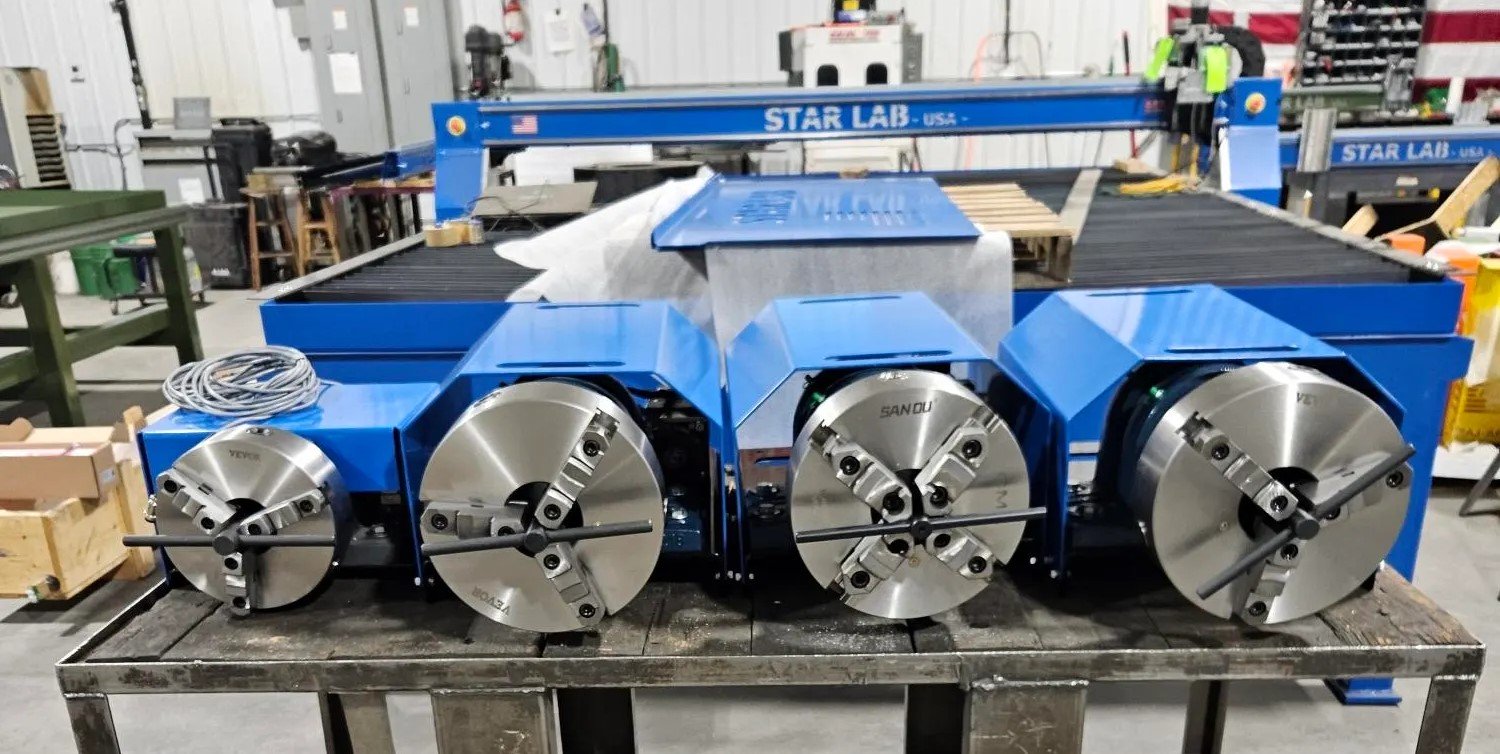

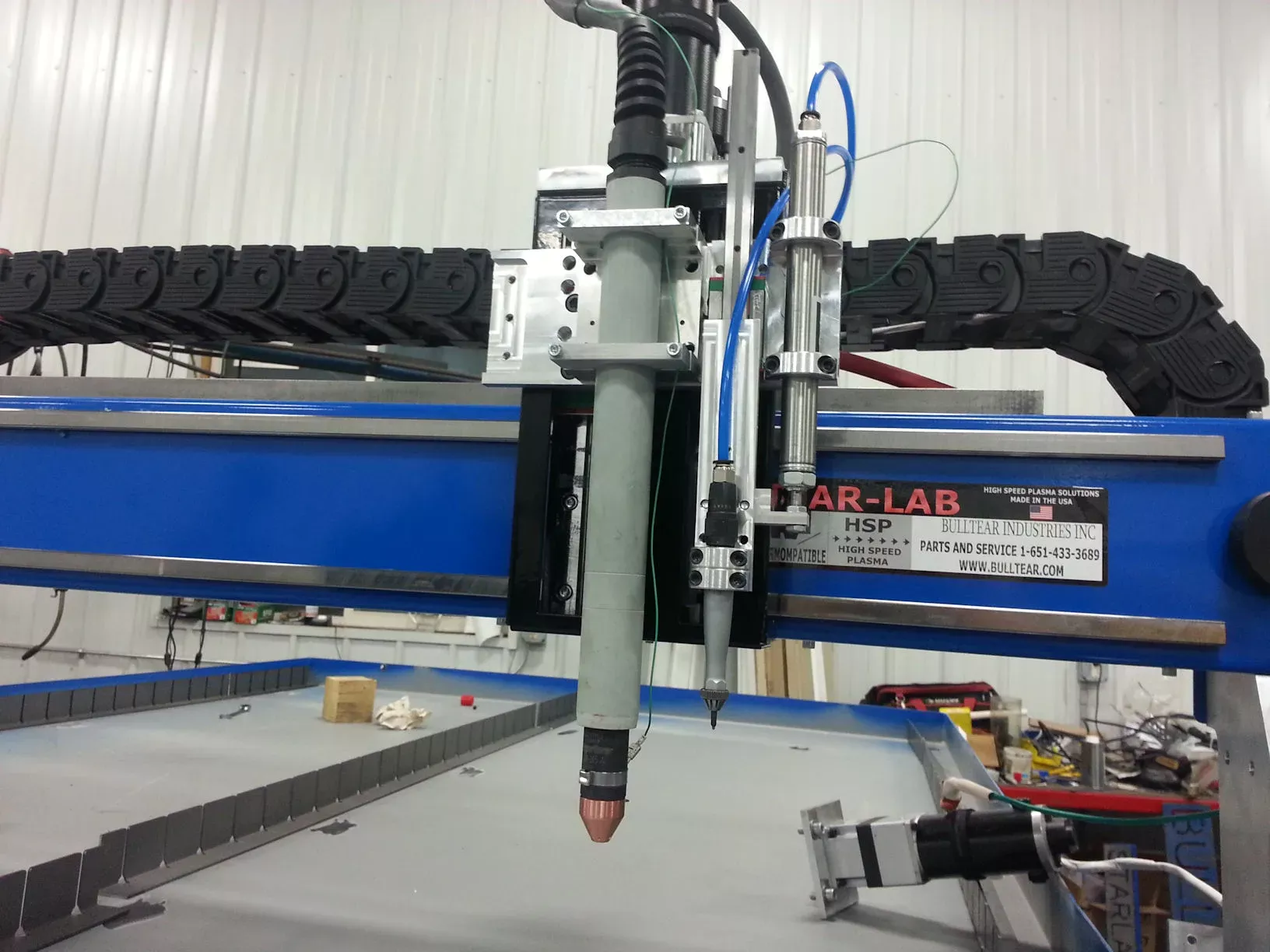

Built like CNC lasers, our platforms combine high-speed plasma (HSP) performance with support for heavy-duty oxy-fuel cutting and compatibility with up to 3hp routers. That's precision, speed, and versatility—all in one machine.

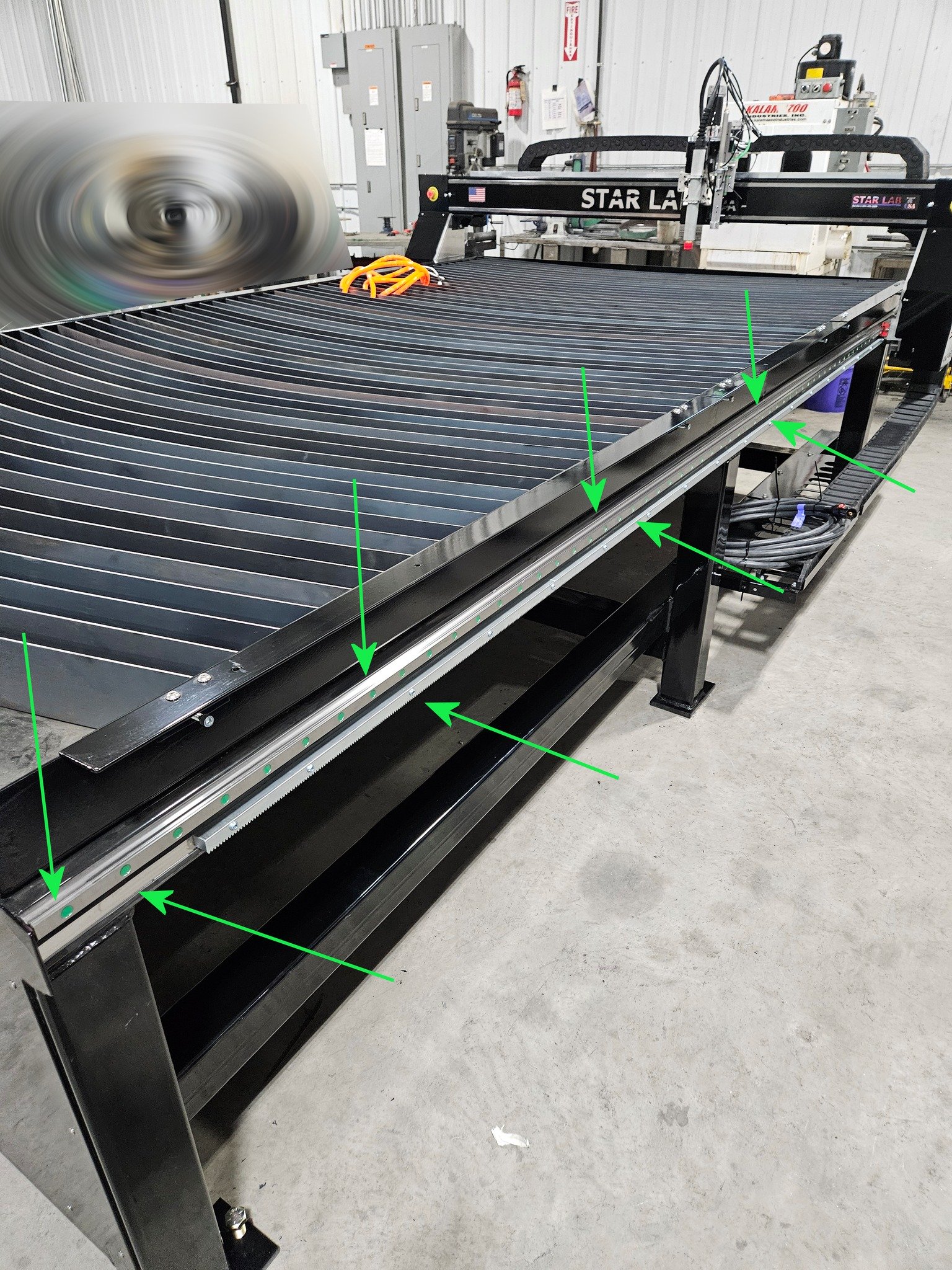

Nothing on our machines is off-the-shelf. From the machined ⅜″–½″ thick gantries to the oversized, fully welded and powder-coated frames, every detail—from collision detection to rail/gear rack integration—is designed to deliver unmatched reliability and accuracy without compromise.

Expect top-tier components and performance as standard. Every system includes:

Superior cut quality with water-cooled cutting surface

Precision height adjustment for optimal cutting

Protects torch from collision damage

Advanced safety system prevents damage

Massive, industrial-strength construction

Enhanced mounting flexibility

Every detail designed for performance and reliability

Take your pick of top-tier CNC systems—CommandCNC or FlashCut—widely regarded as the best plasma controllers in the industry.

Professional-grade control system

Industry-leading performance

Advanced options for power users

From design to delivery - see how Star Lab CNC machines are built

State-of-the-art manufacturing in Minnesota

Precision welding and machining

100% assembled before shipping

Rigorous quality control testing

Decades of combined CNC and plasma cutting expertise

Dedicated support team available when you need us

Our machines are designed, tested, and built here in the USA. Whether you're in industrial fabrication, a school workshop, or crafting HVAC parts, Star Lab CNC has the range, performance, and reliability to get the job done—every time.

Designed, tested, and built in America

Discover why fabricators trust Star Lab CNC for precision, reliability, and lifetime support.